AC drive in constant pressure water supply system

Constant pressure water supply system characteristics

- Electricity saving ratio up to 20%-40% percent.

- Small installation space, low cost with high efficiency.

- Comprehensives function with flexible configuration.

- Soft start/stop feature can eliminate water hammer impact, and reduce average torque and attrition on motor axis to lower maintenance cost and prolong water pump's service life.

- Control the drive system through network communication to achieve automation management to save human source.

Energy saving principle

According to the water pump working principle: the water flow is direct ratio to the water pump's motor speed, the water pump's lift is direct ratio to the square of water pump motor's speed, and the shaft power is equal to the product of water flow and list, so the shaft power is direct ratio to the cube of motor speed. Therefore, the water pump's power can be changed by the pump motor's speed.

The flow formula: Q∝N H∝N2 KW=Q*H∝N3

Q means flow,N means speed,H means lift,KW means shaft power.

For example: the frequency reduce from 50HZ to 45HZ, then P45/P50=(45/50)3= 0.729, i.e. P45=0.729 P50;

The frequency reduce from 50HZ to 40HZ, then P40/P50=(40/50)3= 0.512, i.e. P40=0.512 P50.

Generally the water pump is determined according to the water supply system's maximum power requirement, but in practical experience, the water supply system doesn't need to work in its maximum power all the time. Normally it adopts throttle valve to control water flow, but the pump motor working in full load all the time, then it wastes electricity consumption. However, after install variable frequency drive to the system, it will work more smooth and stable, to control water supply by adjusting pump motor speed, and earn investment back by electricity saving in low speed running.

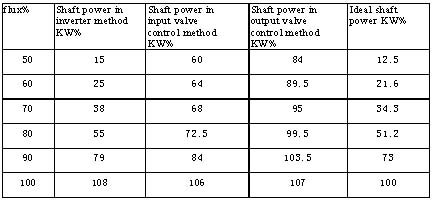

Here is the form to see the difference between 3 flow control modes by a 100kW water supply system electricity consumption:

Lots of motor driving systems have overmeasure, low working efficiency, high power consumption, high starting current and loud operation noise etc., which will affect company's efficiency. However, the variable frequency drive can solve these problems, generally we can expect earning investment back within 10 months by improve the system working conditions.

Main applications of variable frequency constant pressure water supply system

1. High-rise buildings, residential area domestic water supply;

2. The application needs constant water pressure control, cooling water circulation, thermal water circulation, boiler water supplement etc.;

3. Central air-conditioning system;

4. Irrigation, sewage treatment, artificial fountain;

5. And other liquid system needs constant pressure control.

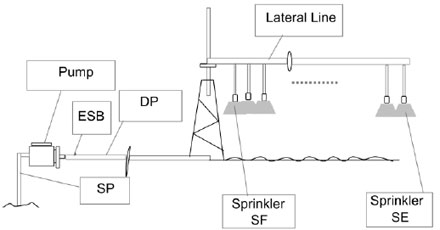

Constant pressure water supply system composition

AC drive is core part of the whole system.

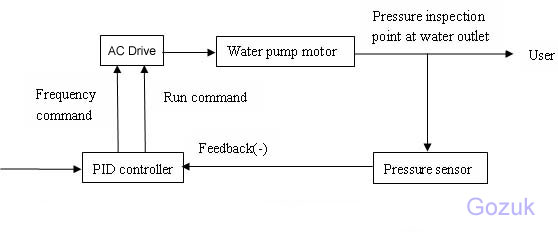

The pump motor is output link, the motor speed is controlled by variable frequency AC drive to achieve variable flow with constant pressure control. The AC drive receives signal from PID controller to control the pump motor speed, pressure sensor detects pipe network water pressure and sends signal to PID controller, and adjusts AC drive's output frequency by PID controller, to achieve a closed-loop control system.

GK3000 series AC drives in constant pressure water supply system

GK3000 series AC drives have integrated PID controller, with perfect dormancy feature to enable maximum energy saving rate.

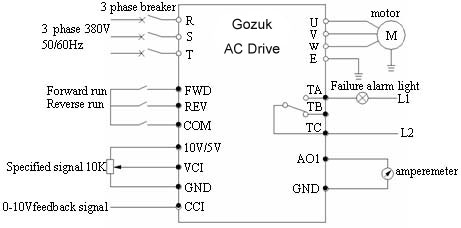

The basic wiring diagram of GK3000 series AC drives in variable frequency constant water supply system.