Variable speed drive in air compressor

Air compressor working principle

The working principle of air compressor is a pair of parallel meshing of male and female rotors (or screw) rotation in the cylinder, which makes the air in the rotor slot continuous produce periodic changes in volume, then the air being transported from suction side to the output side along with the rotor axis, to achieve screw compressor suction, compression and exhaust process.

Traditional air compressor driving system characteristics:

Constant torque feature, the motor shaft power PL is in direct ratio with the motor rotation speed;

Most air compressors are in long time operation, but the load changes frequently, so it’s a variable load;

It requires high starting torque due to the flywheel big moment;

Rare start-up times, no special requirements in accelerating and decelerating time;

Most air compressors have automatic loading/unloading features, but the load will change suddenly in loading/unloading period.

Air pressure is the main control object of the air compressor, and takes temperature as control parameter in freezing or cooling system. General control mode:

Adjusting the valve opening in inlet or outlet manually; Adopt mechanical ways in automatic loading/unloading controls; Adjusting pressure or flow by changing the blade angles.

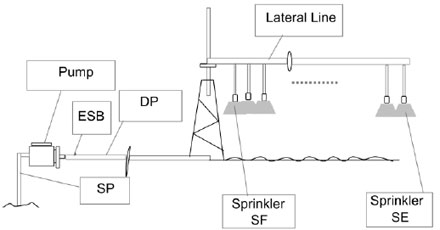

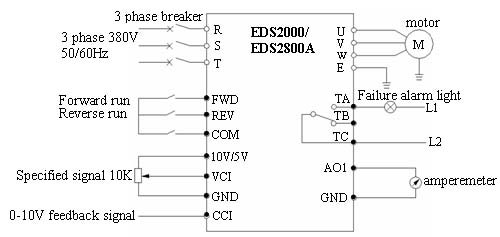

Variable speed drive wiring for air compressor

Energy saving with variable speed drives in air compressor

As the air compressor maybe in long time operation at its full load condition, so it needs determine the motor capacity according to the air compressor maximum requirement, then the motor capacity is generally higher. In practical operation, light load running rates maybe in a high proportion. Therefore, adopts variable speed dive can improve working efficiency and save energy greatly.

In some cases, the electric motor running power cannot lower even if air compressor don’t need to full load operation. But, the variable speed drive can control the electric motor in lower speed running in this case to achieve energy saving.

Normally, a single motor driving system cannot adjust consecutively according to load capacity. However, we can easy adjust speed consecutively after adopting variable speed drives to the air compressor, and keep air pressure, flow and temperature stable, thus to improve the air compressor working performance greatly.