GK200 Solar Pump Inverter in Water Supply System

IntroductionEnergy and water saving irrigation is an important symbol of modern agricultural development, lack of electricity, less electricity in, no electricity,

the power supply is not normal region, automatic water irrigation has been a very big headache problem. Even if the power supply can ensure the region's electricity supply facilities (including high voltage lines, transformers, power switches, etc.) are also large investment, high efficiency damage (including theft), the utilization of low infrastructure investment, especially in agriculture irrigation power facilities.

the power supply is not normal region, automatic water irrigation has been a very big headache problem. Even if the power supply can ensure the region's electricity supply facilities (including high voltage lines, transformers, power switches, etc.) are also large investment, high efficiency damage (including theft), the utilization of low infrastructure investment, especially in agriculture irrigation power facilities.After the water supply system using photovoltaic solar cells directly convert solar energy into direct current energy, through a series of microelectronics and power electronics to convert DC to work after a three-phase AC drive pump. It is nearly 10 years to budding mechatronics worldwide high-tech products, which embodies the energy conversion, new motor, MPPT, frequency converter and a series of micro-electronics technology and software applications, and many other high-tech technology.

The principle of solar photovoltaic water systems

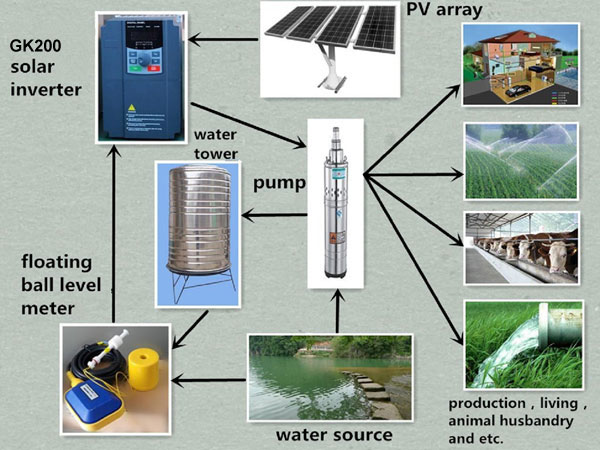

1) The system consists of solar arrays, solar pump inverter, transfer pumps and plumbing systems, water and reservoir water level detection devices;

- Solar cell array: convert solar energy into direct current;

- Solar energy converter: DC solar cells will be converted to a three-phase alternating current supplied to drive the pump work;

- Transmission system pumps and pipes: by pumps, pipes and ditches and other water sources of water will be delivered to the water or water storage areas;

- Water level detection device: detect water sources and reservoirs of water, protect the motor in the water supply to meet the requirements of the premise.

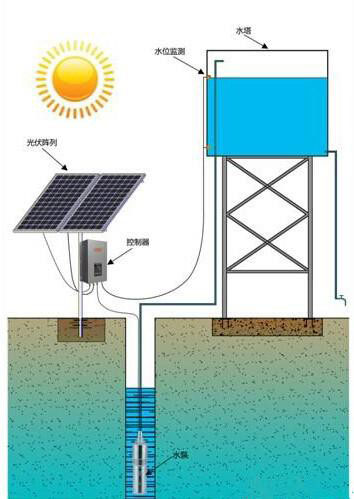

3) Solar pump water supply system appearance

4) Solar pump water supply system application site

5) Solar pump water supply system diagram

6) Solar water system works

Solar photovoltaic cell array through series or parallel, solar pump inverter, batteries meet the requirements of the DC power supply, inverter-driven water pump working again, pumping water from the reservoir, or other container, for life, livestock, agricultural irrigation, industrial production such as water. Water sources and reservoirs mounted liquid level detection sensor to detect water level changes. When the water level reaches the lower water level limit of the detection, or reservoir water level reaches the upper limit of the detection level, solar pump inverter promptly shut down can protect the motor and avoid wasting water.

7) The application principle of solar pump inverter

MPPT is the Maximum Power Point Tracking for short, MPPT controller can detect the real-time voltage of the solar panel power generation, and track the maximum voltage and current values (VI), the system with the highest efficiency of the battery, inverter capacitor charging. Solar pump inverter in photovoltaic system plays an important role in coordinating solar panels, batteries, workload, is an integral component of the PV system. Software unique MPPT algorithm to detect in real time via the controller solar panel power voltage regulator output frequency, fast dynamic response, the motor is always working at peak efficiency, so that the solar photovoltaic panels to maximize economic efficiency.

Solar photovoltaic energy conversion efficiency is impacted by the supply characteristics, factors such as light intensity and angle of the output voltage fluctuations, GK200 solar pump inverter wide voltage design is enable to ensure the inverter can still work normally under low voltage.

GK200 solar pump inverter field application program

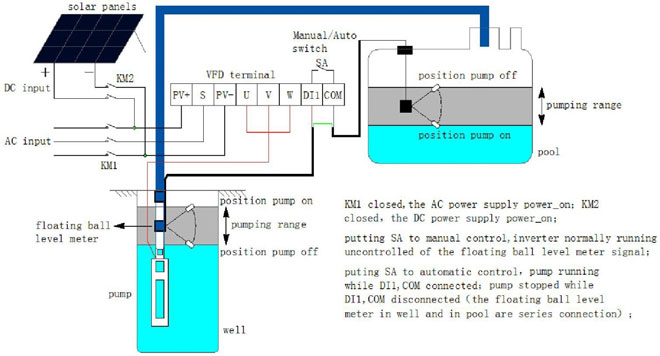

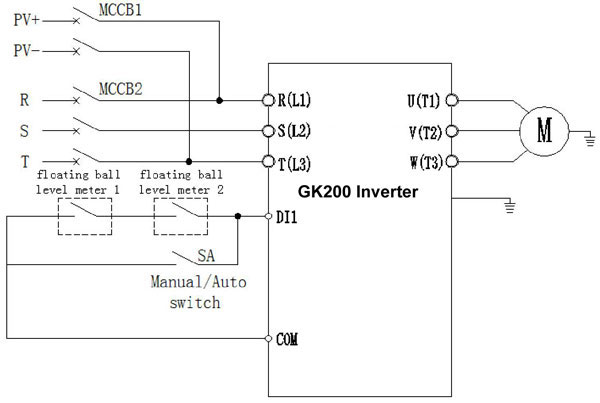

1) Electrical schematics

2) Parameter setting

| Function code | Function description | Setting value | Function |

| P01.01 | Terminal command channel | 1 | Terminal control operation |

| P01.03 | Frequency command selection | 11 | MPPT set the operating frequency |

| P01.11 | Acceleration time1 | 20s | The maximum frequency |

| P01.12 | Acceleration time1 | 10s | Upper frequency |

| P02.11 | Power terminal running protection selection | 1 | The time of the power terminal run command |

| P06.00 | DI1 terminal function selection | 1 | DI1 Forward |

| Other settings are all factory default values | |||

3) Advantages of the application program

- MPPT is the Maximum Power Point Tracking (MPPT) for short, MPPT controller capable of real-time detection of solar panels power voltage, and track the maximum voltage and current values (VI), the system with the highest efficiency of the battery, inverter capacitor charging. Solar pump inverter in photovoltaic system plays an important role in coordinating solar panels, batteries, workload, is an integral component of the PV system. Software unique MPPT algorithm to detect in real time via the controller solar panel power voltage regulator output frequency, fast dynamic response, the motor is always working at peak efficiency, so that the solar photovoltaic panels to maximize economic efficiency;

- GK 200 solar pump inverter main power input can either use solar photovoltaic DC power supply, also can use battery, mains power. Simple wiring and control, truly multi-power mode, then solar pump inverter can expand the practical application;

- Cooperated with water level sensor, the solar pump inverter can be controlled according to customer requirements for automatic operation or manual operation, intelligent control, not only meet the production and living water, but also protect the motor, avoid wasting water;

- Lower system cost and applicability stronger, can be widely used in agricultural irrigation, orchard irrigation, villa or remote villages, station, posts, field on duty (duty) Automatic water supply system point;

- Wide voltage design, the solar pump inverter can remain stable at high and low voltage, high product adaptability;

- Inverter over-current, overload, overvoltage, undervoltage, lack of equal protection, full protection of the motor.

- Should choose the appropriate number of solar cells and the correct connection of solar cells based on inverter specifications and parameters, as this may damage the solar pump inverter;

- When the motor is far away from the inverter, the leakage current between conductors will increase, should consider at the output of the inverter output reactor or install a filter;

- The solar pump inverter can be powered by solar cells, you can use the battery, AC power supply, please select the appropriate power supply and control circuit according to the actual application;

- Single-phase AC power supply, please contact L1 (R), L3 (T) terminal;

The system need not be laying power lines without loading transformers, power switching and other facilities, according to the actual situation of the environment and the actual configuration of the power system needs of any size, you can always supply. Can storage water, can also be manually controlled unmanned facilitate ease.