Variable Frequency Drive Load Types

The potential for variable frequency drive (VFD) energy saving from slowing down the load depend on the characteristics of the load being driven. There are three main types of load: variable torque, constant torque and constant power.

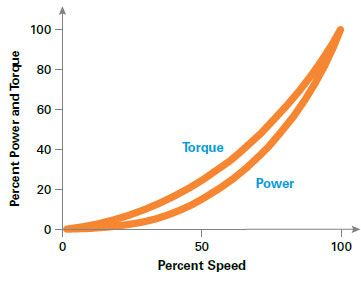

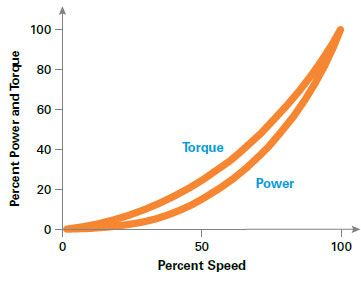

Variable torque load

Variable torque loads are typical of centrifugal fans and pumps and have the largest energy saving potential controlled by variable frequency drives. They are governed by the Affinity Laws which describe the relationship between the speed and other variables.

The change in flow varies in proportion to the change in speed:

The power – speed relationship is also referred to as the 'Cube Law'. When controlling the flow by reducing the speed of the fan or pump a relatively small speed change will result in a large reduction in power absorbed.

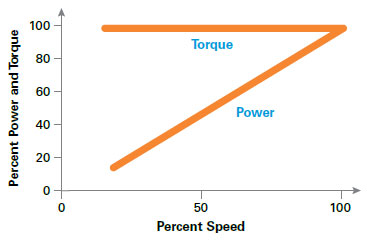

Constant torque load

Typical constant torque applications controlled by variable frequency drives include conveyors, agitators, crushers, surface winders and positive displacement pumps and air compressors.

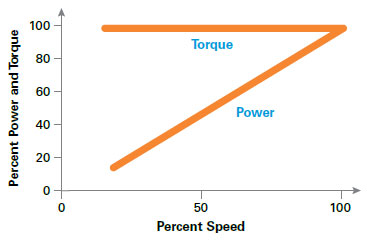

On constant torque loads the torque does not vary with speed and the power absorbed is directly proportional to the speed, this means that the power consumed will be in direct proportion to the useful work done, for example, a 50% speed reduction will result in 50% less power being consumed.

Although the variable frequency drive energy savings from speed reduction are not as large as that with variable torque loads, they are still worth investigating as halving the speed can halve the energy consumed.

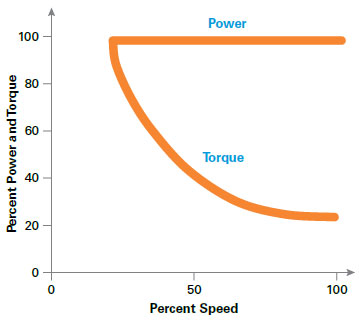

Constant power load

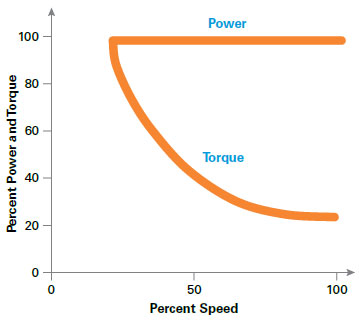

On constant power loads the power absorbed is constant whilst the torque is inversely proportional to the speed. There are rarely any energy savings opportunities from a reduction in speed. Examples of constant power applications include center winders and machine tools.

Variable torque load

Variable torque loads are typical of centrifugal fans and pumps and have the largest energy saving potential controlled by variable frequency drives. They are governed by the Affinity Laws which describe the relationship between the speed and other variables.

The change in flow varies in proportion to the change in speed:

Q1/Q2 = (N1/N2)The change in head (pressure) varies in proportion to the change in speed squared:

H1/H2 = (N1/N2)2The change in power varies in proportion to the change in speed cubed:

P1/P2 = (N1/N2)3Where Q = volumetric flow, H = head (pressure), P = power, N = speed (rpm)

The power – speed relationship is also referred to as the 'Cube Law'. When controlling the flow by reducing the speed of the fan or pump a relatively small speed change will result in a large reduction in power absorbed.

Constant torque load

Typical constant torque applications controlled by variable frequency drives include conveyors, agitators, crushers, surface winders and positive displacement pumps and air compressors.

On constant torque loads the torque does not vary with speed and the power absorbed is directly proportional to the speed, this means that the power consumed will be in direct proportion to the useful work done, for example, a 50% speed reduction will result in 50% less power being consumed.

Although the variable frequency drive energy savings from speed reduction are not as large as that with variable torque loads, they are still worth investigating as halving the speed can halve the energy consumed.

Constant power load

On constant power loads the power absorbed is constant whilst the torque is inversely proportional to the speed. There are rarely any energy savings opportunities from a reduction in speed. Examples of constant power applications include center winders and machine tools.

You may also like:

We get at the poles of the system by looking at the characteristic equation, 1+T(s). Unfortunately, we don't have the math available (except in classroom exercises) we have an empirical system that may or may ...

As per Torque/Slip characteristic for AC Motor, the value of the Max. Torque can be developed is constant while the Starting Torque occurs @ S=.1, (T proportional to r2 and S also proportional to r2 where r2 ...

In a balanced 3-phase system with pure sine waves, the neutral current is zero, ideally.

If there is phase imbalance, it shows up in the neutral, so check for imbalance.

The other major cause of high neutral ...

KW is true power and KVA is apparent power. In per unit calculations the more predominantly used base, which I consider standard is the KVA, the apparent power because the magnitude of the real power (KW) is ...

When the transition between wye and delta takes place, be very sure that that the mechanical interlocks on the contractors are properly adjusted. If one doesn't completely open before the other closes, you ...

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

How much investment in solar power plant for 100kw?

ONE of my diesel generator 1400kva trips down

Induction motor 415 volt, 16A FLA taking current 9A, 29A, 21A

Problems overcoming check valve on fire pump system

question: I am in a debate concerning motion.

Spur growth and demand for Electric Motors in India.

We are developing machine using 11 servo controllers of Allen Bradley K300

Should SCADA PC, HMI, PLC, DCS be on the same existing IT NETWORK

ONE of my diesel generator 1400kva trips down

Induction motor 415 volt, 16A FLA taking current 9A, 29A, 21A

Problems overcoming check valve on fire pump system

question: I am in a debate concerning motion.

Spur growth and demand for Electric Motors in India.

We are developing machine using 11 servo controllers of Allen Bradley K300

Should SCADA PC, HMI, PLC, DCS be on the same existing IT NETWORK