Home » Blog » Energy saving » Variable Air Volume System Optimization

Variable Air Volume System Optimization

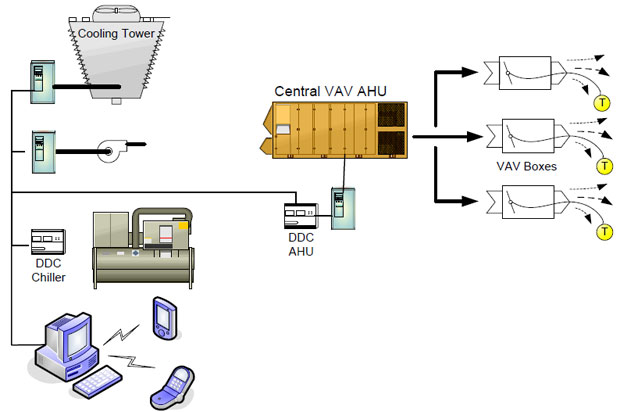

Variable Air Volume Systems (VAV) can be optimized to increase energy savings by maximizing the efficiency of the equipment at part-load conditions. The goal with the optimization strategy is to run each subsystem (chiller, cooling tower, Airhandler, etc) in the most efficient way possible while maintaining the current building load requirement.

As each Variable Air Volume terminal controls the space temperature - based on flow the worst case zone can easily be identified by an automation system. The supply fan speed can be reduced by resetting the static pressure (see following page). As the load drops and the fan meets a preset minimum flow, the system resets the air temperature up, so less chilled water is needed. In a variable flow chiller system, this reduces pumping energy.

If the system load continues to drop, the system will reset the chiller supply water temperature upward which will then reduce the energy requirements of the chiller. Changes in the chiller head pressure and loads can then reset the cooling tower fan speed.

The key to optimizing the system operation is communication and information sharing through the entire system equipment. With the reduced cost of variable frequency drives and Building Automation Systems, (BAS) complete system optimization can be implemented as a cost effective option.

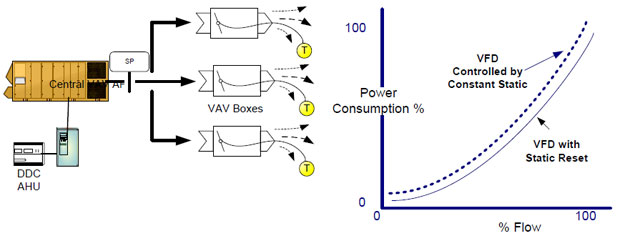

In VAV systems where the individual VAV boxes and the AHU are on a building automation system, additional savings can be achieved by implementing static pressure reset. The static pressure sensor in a VAV system is typically located two-thirds of the way downstream in the main supply air duct for many existing systems. Static pressure is maintained by modulating the fan speed.

When the static pressure is lower than the setpoint, the fan speeds up to provide more airflow (static) to meet the VAV box needs, and vice-versa. A constant set point value is usually used regardless of the building load conditions.

Under partial-load conditions the static pressure required at the terminal VAV boxes may be far less than this constant set point. The individual boxes will assume a damper position to satisfy the space temperature requirements. For example, various VAV box dampers will be at different damper positions, (some at 70% open, 60% open, etc) very few will be at design, ie 95% -100% open.

RESET STRATEGY

Essentially, resetting supply air static pressure requires that every VAV box is sampled with the static reset set to the worst case box requirement. For example, each box is polled, every 5 minutes. If no box is more than 95% open, reduce duct static pressure set point by 5%. If one or more boxes exceed 95% open, increase static pressure set point by 5%.

With a lower static set point to maintain, fan speed reduces. The result is increased energy savings in the 3 to 8% range. See figure below. If the BAS system is already installed, implementing this strategy is relatively free.

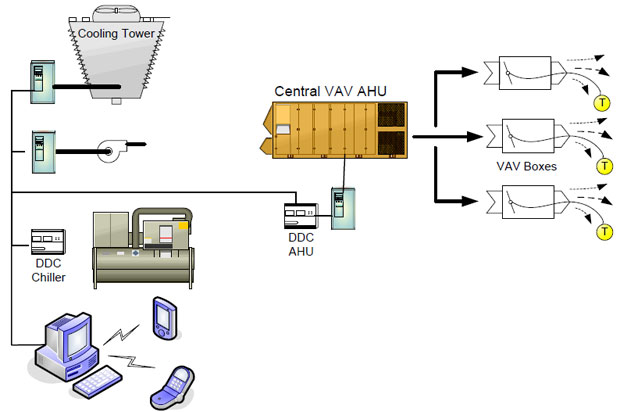

As each Variable Air Volume terminal controls the space temperature - based on flow the worst case zone can easily be identified by an automation system. The supply fan speed can be reduced by resetting the static pressure (see following page). As the load drops and the fan meets a preset minimum flow, the system resets the air temperature up, so less chilled water is needed. In a variable flow chiller system, this reduces pumping energy.

If the system load continues to drop, the system will reset the chiller supply water temperature upward which will then reduce the energy requirements of the chiller. Changes in the chiller head pressure and loads can then reset the cooling tower fan speed.

The key to optimizing the system operation is communication and information sharing through the entire system equipment. With the reduced cost of variable frequency drives and Building Automation Systems, (BAS) complete system optimization can be implemented as a cost effective option.

In VAV systems where the individual VAV boxes and the AHU are on a building automation system, additional savings can be achieved by implementing static pressure reset. The static pressure sensor in a VAV system is typically located two-thirds of the way downstream in the main supply air duct for many existing systems. Static pressure is maintained by modulating the fan speed.

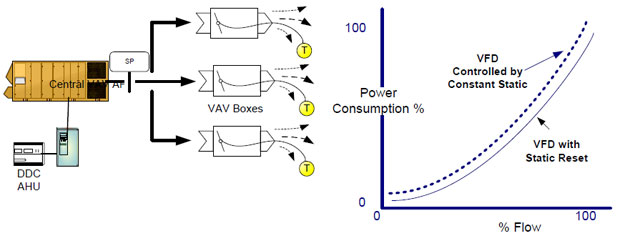

When the static pressure is lower than the setpoint, the fan speeds up to provide more airflow (static) to meet the VAV box needs, and vice-versa. A constant set point value is usually used regardless of the building load conditions.

Under partial-load conditions the static pressure required at the terminal VAV boxes may be far less than this constant set point. The individual boxes will assume a damper position to satisfy the space temperature requirements. For example, various VAV box dampers will be at different damper positions, (some at 70% open, 60% open, etc) very few will be at design, ie 95% -100% open.

RESET STRATEGY

Essentially, resetting supply air static pressure requires that every VAV box is sampled with the static reset set to the worst case box requirement. For example, each box is polled, every 5 minutes. If no box is more than 95% open, reduce duct static pressure set point by 5%. If one or more boxes exceed 95% open, increase static pressure set point by 5%.

With a lower static set point to maintain, fan speed reduces. The result is increased energy savings in the 3 to 8% range. See figure below. If the BAS system is already installed, implementing this strategy is relatively free.

You may also like:

Due to variable frequency drive can adapt to various requirements in production process, especially in the industrial automation control applications, AC variable frequency control technology has risen to be ...

If you are interested in power electronics design at the board or system level, I would recommend LTspice (note the correct spelling) by far above all the others. In addition to being superb for IC design ...

Two electrical motors that design for altitude <1000 m but now this two electrical motor have installed on altitude 1880 m and this electrical motors become very hot. The electrical machines power is ...

I have used Microchip and TMS320 to develop VFD for various applications. To give you a top level view, The TMS320 is a high end solution - a lot of commercial variable frequency drive uses TMS320 DSP. Quite a ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during motor start up, avoid the motor being burned out, and provide protection in ...

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

Insulation Resistance of generator stator drops

Advantages/Disadvantages of String inverters vs. Central inverters?

Simulation and Modelling, who uses it, and for what?

What is the relationship between inducer and NPSH?

General purpose software tool for designing multiple output flyback converters

Vibration in Vertical Pumps

Voltage Frequency Calculations

VALUE ENGINEERING ON CABLING SYSTEM FOR POWER PLANT

Advantages/Disadvantages of String inverters vs. Central inverters?

Simulation and Modelling, who uses it, and for what?

What is the relationship between inducer and NPSH?

General purpose software tool for designing multiple output flyback converters

Vibration in Vertical Pumps

Voltage Frequency Calculations

VALUE ENGINEERING ON CABLING SYSTEM FOR POWER PLANT