Home » Blog » Energy saving » Boosting Efficiency in Water-Jet Cutting Systems

Boosting Efficiency in Water-Jet Cutting Systems

Water-jet cutting is a subtractive manufacturing process that uses a high-pressure stream of water, with or without an abrasive, to cut materials with exceptional precision.

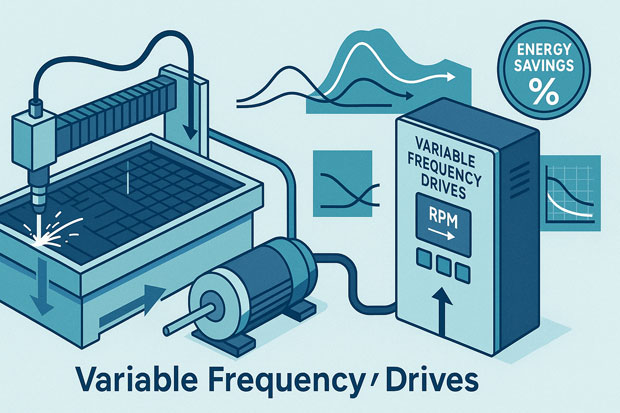

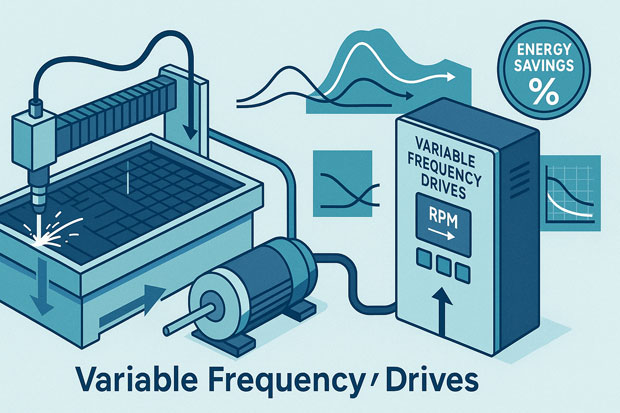

This guide shows how variable frequency drives increase efficiency, stabilize cut quality, and extend component life in real shops, not just on paper.

The hook is simple. Electricity prices bite, seals wear, and schedules slip when pumps run harder than they should.

Studies in industrial pumping report energy savings of 20 to 50 percent when speed is matched to demand, and water-jet cells are no exception.

You will learn where VFDs fit, how they work with pumps and peripherals, what to spec, and what the cost curve looks like.

By the end, you will know how to plan a right-sized retrofit and measure results with data, not anecdotes.

What is water-jet cutting, and where do VFDs fit?

Water-jet cutting is a CNC process that propels water at ultra-high pressure through a small orifice to erode material along a programmed path.

Abrasive water-jet cutting introduces garnet into the stream to cut metals, stone, and composites that plain water cannot handle.

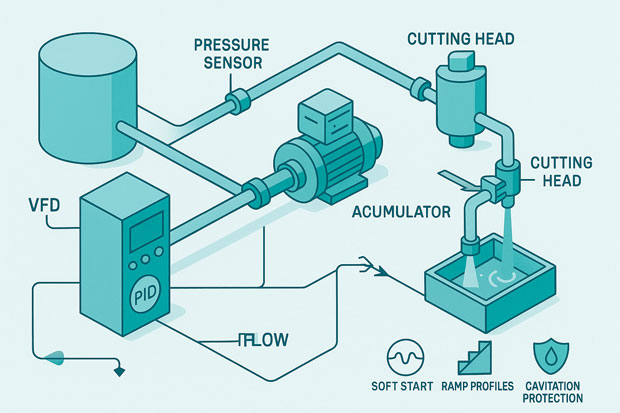

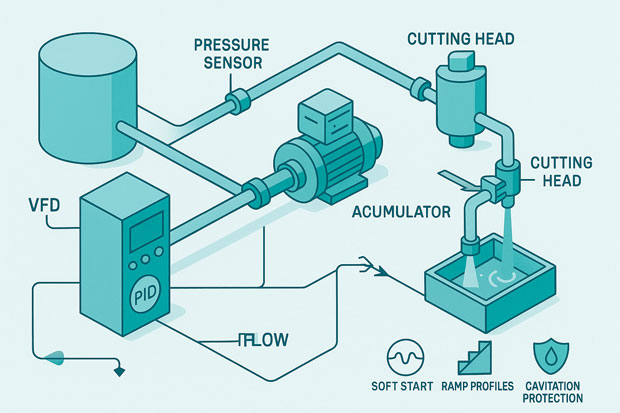

The system includes a high-pressure pump or intensifier, accumulators, valves, a motion platform, and a control that synchronises pressure with feed.

A variable frequency drive is a power electronics device that regulates motor speed and torque so the pump output matches the instantaneous pressure and flow demand.

VFDs fit at the heart of the cell. They control the pump motor during startup, piercing, dwell, and shutdown when load swings rapidly.

They also govern auxiliaries such as chillers, fans, abrasive feeders, and booster pumps to prevent energy waste during idle or partial load.

Common operating states where VFDs help

Variable Frequency Drive (VFD)

A variable frequency drive is a technology that converts fixed-frequency AC into a variable-frequency, variable-voltage supply to control motor speed and torque with precision.

The VFD is suitable for water-jet cutting because the pump load varies, pressure must remain stable, and components last longer when acceleration is gentle.

The working principle is straightforward. A rectifier produces DC, a DC bus stores energy, and an inverter synthesises AC at the required frequency.

Control modes range from simple V/Hz to sensorless vector and full closed-loop with encoder or pressure feedback for tight regulation.

In practice, the drive enforces soft acceleration and deceleration, applies torque limits, and runs PID to hold setpoint pressure.

Ancillary motors for abrasive feed, cooling, and ventilation can all be trimmed to actual need to save power and noise.

Essential components

How do VFDs improve efficiency in water-jet cutting?

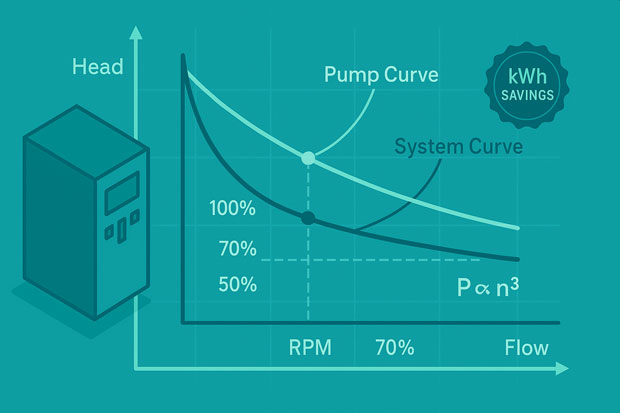

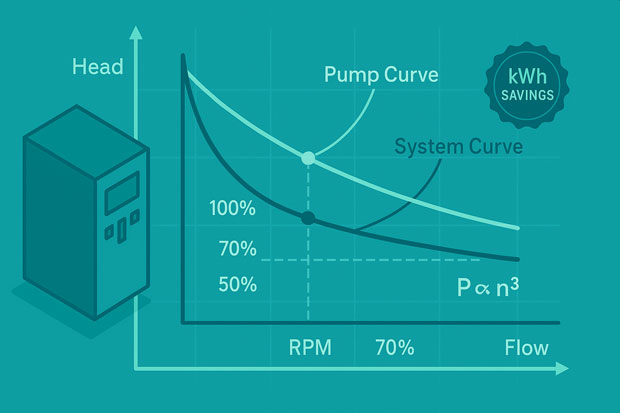

VFDs improve efficiency by aligning pump speed with process demand, allowing the system to avoid throttling losses and maintain pressure with less energy.

Pump affinity laws state that power varies roughly with the cube of speed, so even modest speed reductions yield significant energy savings.

Smoother pressure means cleaner edges and fewer recuts because the jet remains coherent during corners and pierces.

Controlled ramps reduce mechanical shock, which protects seals, bearings, and check valves, and lowers unplanned downtime.

Closed-loop pressure control with a well-tuned PID maintains setpoint under changing orifice wear, abrasive flow, and path dynamics.

Data logging on the drive or PLC exposes idle time, overshoot, and cavitation events so you can trim them away methodically.

Main efficiency levers

Where should VFDs be applied in a water-jet system?

VFDs should be applied first to the high-pressure pump motor because pressure stability and energy use are primarily associated with it.

They should then be considered for intensifiers or servo-driven pumps where applicable, and for the abrasive feeder that benefits from consistent dosing.

Secondary but valuable placements include the chiller or cooling pump, ventilation fans, abrasive conveyors, and booster pumps that maintain inlet conditions.

Each motor gets the control mode it deserves, from sensorless vector for general duty to closed-loop with encoder or direct pressure feedback for the pump.

In the first third of any upgrade project, it helps to benchmark a proven machine platform.

For readers exploring purpose-built systems, reviewing high-precision water-jet cutting systems provides context on pump architectures, duty cycles, and control strategies that respond well to VFDs.

Main placements and goals

High-pressure pump motor

A high-pressure pump is a machine that pressurizes water to tens of thousands of PSI so the jet can cut tough materials at speed.

The machine is usable with VFDs because flow demand fluctuates across pierces, straights, and corners, and throttling excess flow wastes energy and wears components.

Main applications include metal plate cutting, stone and ceramic processing, and composite trimming in aerospace and automotive.

The working principle is either direct-drive plunger pumping or intensifier-type multiplication, both of which benefit from controlled acceleration and pressure regulation.

Commissioning tips matter. Pressure sensor placement affects noise in the loop, minimum speed limits prevent overheating, and accel-decel times avoid water hammer.

Torque response at low RPM should be verified, and PID gains should be tuned under real cut programs, not just static tests.

Commissioning checklist

Step-by-step: How to size and set up a VFD for a water-jet cutter

This section outlines the main steps from load analysis to final tuning so your setup works on day one.

There are exactly seven steps that guide a practical specification and commissioning path.

What are the advantages of adding VFDs to existing water-jet systems?

The chief advantages are lower energy use, steadier pressure, faster cycles, and longer component life, followed by cleaner power and better diagnostics.

There are 7 advantages that cover shop-floor performance and finance.

What are the limitations or pitfalls to watch out for?

Every upgrade brings trade-offs, and VFDs are no exception, especially in harsh, abrasive environments.

There are 6 limitations that you should budget for and design around.

VFD vs. Soft Starter for water-jet pumps

A VFD provides continuous speed control and superior energy savings while a soft starter provides gentle starts and stops without part-load efficiency gains.

Both reduce mechanical stress compared with across-the-line starting, but only the VFD stabilises pressure dynamically during the cut.

Consider control capability, pressure stability, energy savings, cost, and commissioning effort when choosing.

If your process load is largely steady and capital is tight, a soft starter may suffice, yet most water-jet cells see variable demand that favors a VFD.

What do VFDs cost for water-jet cutters in 2025?

Typical VFD packages for water-jet pumps range from a few thousand to several tens of thousands in USD or EUR depending on power, enclosure, and options.

Small units up to about 15 kW often land around 1,000 to 3,000, mid-range 22 to 55 kW around 3,000 to 8,000, and large 75 to 160 kW around 8,000 to 25,000 including basic accessories.

Integration and commissioning may add materially to the total and should be planned from the start.

Budget also for sensors, harmonic mitigation, and thermal management appropriate to abrasive dust and humidity.

There are 6 cost factors that dominate quotes

High-impact applications and use cases

VFDs pay back fastest in materials and workflows that swing between pierce, cornering, and long traverses where demand fluctuates strongly.

There are 7 applications that consistently show measurable improvements in energy per part and cut quality.

Conclusion

VFDs align pump output with real-time demand so water-jet cutting cells consume less energy, hold pressure steadier, and keep seals alive longer.

The most important takeaways are simple to remember and impactful to apply.

First, target the pump motor for the biggest win and pair it with clean pressure feedback.

Second, size the drive realistically, mitigate EMC, and tune the PID under real motion, not just at idle.

Third, instrument the cell and verify savings with trend logs so the business case endures past the first month.

Next steps

This guide shows how variable frequency drives increase efficiency, stabilize cut quality, and extend component life in real shops, not just on paper.

The hook is simple. Electricity prices bite, seals wear, and schedules slip when pumps run harder than they should.

Studies in industrial pumping report energy savings of 20 to 50 percent when speed is matched to demand, and water-jet cells are no exception.

You will learn where VFDs fit, how they work with pumps and peripherals, what to spec, and what the cost curve looks like.

By the end, you will know how to plan a right-sized retrofit and measure results with data, not anecdotes.

- Main promises

- Energy savings through speed control

- Smoother pressure and cleaner edges

- Longer seal and pump life

- Smarter automation and diagnostics

What is water-jet cutting, and where do VFDs fit?

Water-jet cutting is a CNC process that propels water at ultra-high pressure through a small orifice to erode material along a programmed path.

Abrasive water-jet cutting introduces garnet into the stream to cut metals, stone, and composites that plain water cannot handle.

The system includes a high-pressure pump or intensifier, accumulators, valves, a motion platform, and a control that synchronises pressure with feed.

A variable frequency drive is a power electronics device that regulates motor speed and torque so the pump output matches the instantaneous pressure and flow demand.

VFDs fit at the heart of the cell. They control the pump motor during startup, piercing, dwell, and shutdown when load swings rapidly.

They also govern auxiliaries such as chillers, fans, abrasive feeders, and booster pumps to prevent energy waste during idle or partial load.

Common operating states where VFDs help

- Startup and spin-up to avoid inrush and water hammer

- Piercing cycles that benefit from shaped ramps

- Kerf transitions and corners that need pressure stability

- Dwell and idle periods where speed can drop safely

- Shutdown where controlled decel protects seals

Variable Frequency Drive (VFD)

A variable frequency drive is a technology that converts fixed-frequency AC into a variable-frequency, variable-voltage supply to control motor speed and torque with precision.

The VFD is suitable for water-jet cutting because the pump load varies, pressure must remain stable, and components last longer when acceleration is gentle.

The working principle is straightforward. A rectifier produces DC, a DC bus stores energy, and an inverter synthesises AC at the required frequency.

Control modes range from simple V/Hz to sensorless vector and full closed-loop with encoder or pressure feedback for tight regulation.

In practice, the drive enforces soft acceleration and deceleration, applies torque limits, and runs PID to hold setpoint pressure.

Ancillary motors for abrasive feed, cooling, and ventilation can all be trimmed to actual need to save power and noise.

Essential components

- Rectifier

- DC bus

- Inverter bridge

- Control and I/O

How do VFDs improve efficiency in water-jet cutting?

VFDs improve efficiency by aligning pump speed with process demand, allowing the system to avoid throttling losses and maintain pressure with less energy.

Pump affinity laws state that power varies roughly with the cube of speed, so even modest speed reductions yield significant energy savings.

Smoother pressure means cleaner edges and fewer recuts because the jet remains coherent during corners and pierces.

Controlled ramps reduce mechanical shock, which protects seals, bearings, and check valves, and lowers unplanned downtime.

Closed-loop pressure control with a well-tuned PID maintains setpoint under changing orifice wear, abrasive flow, and path dynamics.

Data logging on the drive or PLC exposes idle time, overshoot, and cavitation events so you can trim them away methodically.

Main efficiency levers

- Match speed to real demand rather than throttle excess flow

- Reduce bypass and valve throttling losses at partial load

- Optimize piercing profiles with shaped acceleration

- Minimize idle consumption with intelligent sleep and wake

- Recover stability after corners to cut rework and scrap

- Extend maintenance intervals by reducing mechanical stress

Where should VFDs be applied in a water-jet system?

VFDs should be applied first to the high-pressure pump motor because pressure stability and energy use are primarily associated with it.

They should then be considered for intensifiers or servo-driven pumps where applicable, and for the abrasive feeder that benefits from consistent dosing.

Secondary but valuable placements include the chiller or cooling pump, ventilation fans, abrasive conveyors, and booster pumps that maintain inlet conditions.

Each motor gets the control mode it deserves, from sensorless vector for general duty to closed-loop with encoder or direct pressure feedback for the pump.

In the first third of any upgrade project, it helps to benchmark a proven machine platform.

For readers exploring purpose-built systems, reviewing high-precision water-jet cutting systems provides context on pump architectures, duty cycles, and control strategies that respond well to VFDs.

Main placements and goals

- High-pressure pump motor for stable pressure and the most significant savings

- Intensifier or servo pump for shaped ramps and efficiency at part load

- Abrasive feeder for consistent mass flow and kerf quality

- Chiller and coolant pump for temperature control without waste

- Fans and conveyors for demand-based ventilation and material handling

- Booster pump for steady inlet pressure and cavitation avoidance

High-pressure pump motor

A high-pressure pump is a machine that pressurizes water to tens of thousands of PSI so the jet can cut tough materials at speed.

The machine is usable with VFDs because flow demand fluctuates across pierces, straights, and corners, and throttling excess flow wastes energy and wears components.

Main applications include metal plate cutting, stone and ceramic processing, and composite trimming in aerospace and automotive.

The working principle is either direct-drive plunger pumping or intensifier-type multiplication, both of which benefit from controlled acceleration and pressure regulation.

Commissioning tips matter. Pressure sensor placement affects noise in the loop, minimum speed limits prevent overheating, and accel-decel times avoid water hammer.

Torque response at low RPM should be verified, and PID gains should be tuned under real cut programs, not just static tests.

Commissioning checklist

- Place the pressure sensor close to the process with clean plumbing

- Set minimum speed to maintain lubrication and cooling

- Use conservative accel and decel ramps to protect seals

- Tune PID under dynamic cutting moves and verify overshoot limits

Step-by-step: How to size and set up a VFD for a water-jet cutter

This section outlines the main steps from load analysis to final tuning so your setup works on day one.

There are exactly seven steps that guide a practical specification and commissioning path.

- Determine load and duty cycle. Quantify kW or HP, torque profile, and daily hours at each load state, including idle and pierce.

- Select control mode. Choose V/Hz for simplicity, sensorless vector for better torque, or closed-loop with encoder or pressure feedback for highest stability.

- Choose drive rating and overload class. Apply IEC or NEMA margins for cyclic loads and verify short-circuit ratings and thermal models.

- Plan power quality. Specify EMC filters, harmonic mitigation, and if needed a DC choke or active front end for grid compliance.

- Engineer protection and wiring. Select the enclosure rating, cable types, motor protection, and cooling appropriate to abrasive environments.

- Program parameters. Configure PID for pressure, set accel and decel ramps, set speed limits, interlocks, and safe stop.

- Validate and tune. Log trends, test real parts, set alarm thresholds, and document a rollback plan for parameters.

What are the advantages of adding VFDs to existing water-jet systems?

The chief advantages are lower energy use, steadier pressure, faster cycles, and longer component life, followed by cleaner power and better diagnostics.

There are 7 advantages that cover shop-floor performance and finance.

- Cut energy use by matching pump speed to actual demand across the cycle

- Stabilize pressure to improve edge quality and reduce secondary finishing

- Shorten cycle time by shaping pierce and cornering profiles intelligently

- Extend seal and pump life by reducing mechanical shock and heat

- Reduce noise and vibration for a safer, calmer work environment

- Improve power factor and manage harmonics with appropriate options

- Enable more innovative diagnostics and IIoT data for predictive maintenance

What are the limitations or pitfalls to watch out for?

Every upgrade brings trade-offs, and VFDs are no exception, especially in harsh, abrasive environments.

There are 6 limitations that you should budget for and design around.

- Increase upfront cost for the drive, enclosure, and integration work

- Complicate EMC and harmonics unless mitigations are correctly specified

- Require adequate cooling and sealed enclosures to survive dust and grit

- Demand careful PID tuning to avoid oscillation and pressure ripple

- Risk drive-induced bearing currents unless grounding and filters are applied

- Necessitate operator training and maintenance updates to exploit new features

VFD vs. Soft Starter for water-jet pumps

A VFD provides continuous speed control and superior energy savings while a soft starter provides gentle starts and stops without part-load efficiency gains.

Both reduce mechanical stress compared with across-the-line starting, but only the VFD stabilises pressure dynamically during the cut.

Consider control capability, pressure stability, energy savings, cost, and commissioning effort when choosing.

If your process load is largely steady and capital is tight, a soft starter may suffice, yet most water-jet cells see variable demand that favors a VFD.

What do VFDs cost for water-jet cutters in 2025?

Typical VFD packages for water-jet pumps range from a few thousand to several tens of thousands in USD or EUR depending on power, enclosure, and options.

Small units up to about 15 kW often land around 1,000 to 3,000, mid-range 22 to 55 kW around 3,000 to 8,000, and large 75 to 160 kW around 8,000 to 25,000 including basic accessories.

Integration and commissioning may add materially to the total and should be planned from the start.

Budget also for sensors, harmonic mitigation, and thermal management appropriate to abrasive dust and humidity.

There are 6 cost factors that dominate quotes

- Power rating and overload class for the pump duty cycle

- Control mode and feedback hardware such as encoders and pressure sensors

- Environmental rating, sealing, and cooling for the electrical cabinet

- Power quality accessories including EMC filters, chokes, or active fronts

- Integration with PLC, HMI, safety circuits, and data logging

- Commissioning, tuning, and operator training to lock in the gains

High-impact applications and use cases

VFDs pay back fastest in materials and workflows that swing between pierce, cornering, and long traverses where demand fluctuates strongly.

There are 7 applications that consistently show measurable improvements in energy per part and cut quality.

- Thick metal plate cutting where pierce shaping saves time and wear

- Stone and ceramic where fragile edges benefit from stable pressure

- Composite laminates where heat damage is avoided and kerf stays tight

- Glass cutting where smooth ramps reduce micro-cracking risk

- Precision aerospace parts where repeatability and documentation matter

- Job-shop mixed materials where demand varies hour to hour

- Education and R&D where wide tuning ranges support experimentation

Conclusion

VFDs align pump output with real-time demand so water-jet cutting cells consume less energy, hold pressure steadier, and keep seals alive longer.

The most important takeaways are simple to remember and impactful to apply.

First, target the pump motor for the biggest win and pair it with clean pressure feedback.

Second, size the drive realistically, mitigate EMC, and tune the PID under real motion, not just at idle.

Third, instrument the cell and verify savings with trend logs so the business case endures past the first month.

Next steps

- Run a baseline audit of duty cycle, pressure variance, and idle time

- Right-size the drive, filters, sensors, and enclosure for your environment

- Commission, log data, and adjust ramps and gains to lock in performance

You may also like:

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable frequency drives) of fans together account for 50% to 60% of the total electricity ...

The Fuse for Electrical Motor is efficient for O/C (Short Circuit, either L-G or L-L) or/and internal fault in the Motor windings. Taking into consideration the fuse rating considering the Starting current of ...

The UPS systems commissioning test and inspection procedures are to conform to;

• BS EN 50091-1:1993 - Specification for Uninterruptible Power Supplies (UPS). General and Safety Requirements, AND

• IEC ...

When two transformers are in a parallel group, a transformer with a higher tap position will typically have a higher (LV side) no-load voltage than the other one with a lower tap position. These unequal ...

Many years ago I had an experience of 4nos 37kW fin-fan motors wrongly connected at site to a star. After running for almost 1 year, the operators reported these motors were very warm and felt unusual. We ...

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

How to properly test directional relays?

Mentoring, a valuable source of learning and maturing as an engineer.

Circuit breaker failure protection

Lead Acid Battery Charging Question

Minimum RPM through a VFD

Distributed Generation (DG)

HART Communication with Siemens PLC

Estimate ROI for BIPV (building integrated photovoltaic)?

Mentoring, a valuable source of learning and maturing as an engineer.

Circuit breaker failure protection

Lead Acid Battery Charging Question

Minimum RPM through a VFD

Distributed Generation (DG)

HART Communication with Siemens PLC

Estimate ROI for BIPV (building integrated photovoltaic)?