DC Drives Basic Operation Principles

DC drives vary the speed of DC motors with greater efficiency & speed regulation than resistor control circuits. Since the speed of a DC motor is directly proportional to armature voltage & inversely proportional to field current, either armature voltage or field current can be used to control speed. To change the direction of rotation of a DC motor, either the armature polarity can be reversed, or the field polarity can be reversed.

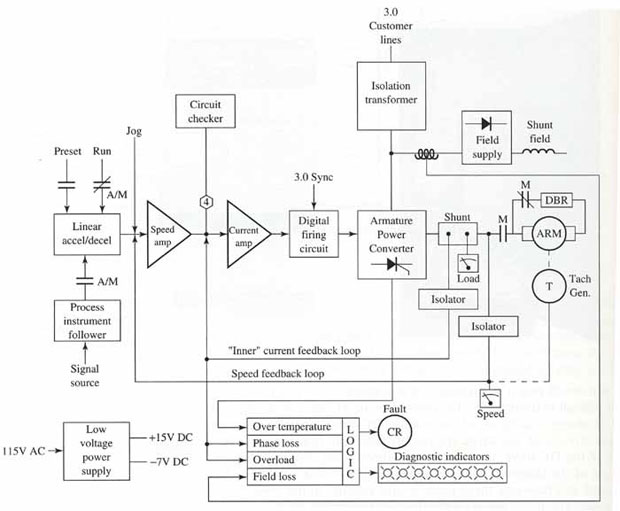

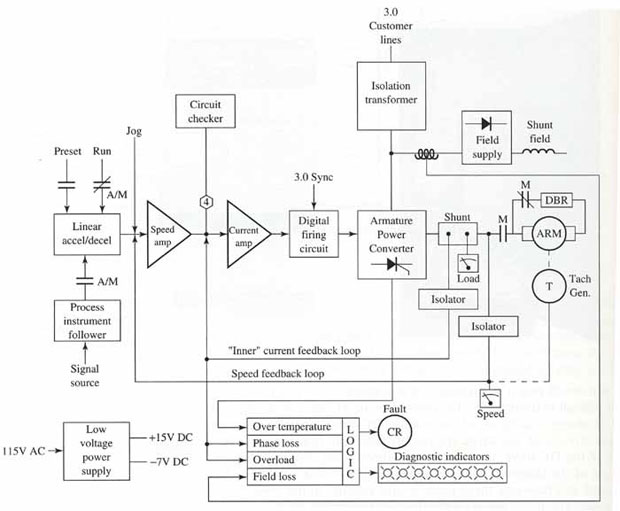

The block diagram of a DC drive system made up of a DC motor & an electronic drive controller. The shunt motor is constructed with armature & field windings. A common classification of DC motors is by the type of field excitation winding. Shunt wound DC motors are the most commonly used type for adjustable-speed control. In most instances the shunt field winding is excited, as shown, with a constant-level voltage from the controller. The SCR (silicon controller rectifier), also known as thyristor, of the power conversion section converts the fixed-voltage alternating current (AC) of the power source to an adjustable-voltage, controlled direct current (DC) output which is applied to the armature of a DC motor. Speed control is achieved by regulating the armature voltage to the motor. Motor speed is directly proportional to the voltage applied to the armature.

The main function of a DC drive is to convert the fixed applied AC voltage into a variable rectified DC voltage.

SCR switching semiconductors provide a convenient method of accomplishing this. They provide a controllable power output by phase angle control. The firing angle, or point in time where the SCR is triggered into conduction, is synchronized with the phase rotation of the AC power source. The amount of rectified DC voltage is controlled by timing the input pulse current to the gate. Applying gate current near the beginning of the sine-wave cycle results in a higher aver age voltage applied to the motor armature. Gate current applied later in the cycle results in a lower average DC output voltage. The effect is similar to a very high speed switch, capable of being turned on & off at an infinite number of points within each half-cycle. This occurs at a rate of 60 times a second on a 60-Hz line, to deliver a precise amount of power to the motor.

The block diagram of a DC drive system made up of a DC motor & an electronic drive controller. The shunt motor is constructed with armature & field windings. A common classification of DC motors is by the type of field excitation winding. Shunt wound DC motors are the most commonly used type for adjustable-speed control. In most instances the shunt field winding is excited, as shown, with a constant-level voltage from the controller. The SCR (silicon controller rectifier), also known as thyristor, of the power conversion section converts the fixed-voltage alternating current (AC) of the power source to an adjustable-voltage, controlled direct current (DC) output which is applied to the armature of a DC motor. Speed control is achieved by regulating the armature voltage to the motor. Motor speed is directly proportional to the voltage applied to the armature.

The main function of a DC drive is to convert the fixed applied AC voltage into a variable rectified DC voltage.

SCR switching semiconductors provide a convenient method of accomplishing this. They provide a controllable power output by phase angle control. The firing angle, or point in time where the SCR is triggered into conduction, is synchronized with the phase rotation of the AC power source. The amount of rectified DC voltage is controlled by timing the input pulse current to the gate. Applying gate current near the beginning of the sine-wave cycle results in a higher aver age voltage applied to the motor armature. Gate current applied later in the cycle results in a lower average DC output voltage. The effect is similar to a very high speed switch, capable of being turned on & off at an infinite number of points within each half-cycle. This occurs at a rate of 60 times a second on a 60-Hz line, to deliver a precise amount of power to the motor.

You may also like:

I never just put power to a first prototype and see what happens. Smoke and loud sounds are the most likely result and then you just know that something was not perfect. So how would you test the next ...

Ahh I see the words machine tool and shop floor; now I can see where you guys are coming from. The type of machines that you talk about were controlled by relay logic and then when technology arrived the ...

When I was doing my PhD in motor design of reluctance machines with flux assistance (switched reluctance machines and flux switching machines with magnets and/or permanently energised coils) my supervisor was ...

Make sure your generator can start your largest motor and that your disconnect breaker or fuses can handle the inrush. I have seen this as an issue, especially when soft starters are used. Soft starters lower ...

The trend toward lower losses in power converters is not apparent in all of the applications of power converters. It is also not apparent that the power converter solution and its losses for a given market ...

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.

Gozuk Blog: all about electric motor control & drives industries development in energy saving applications.Featured

Like pumps, fans consume significant electrical energy while serving several applications. In many plants, the VFDs (variable ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

A frequency inverter controls AC motor speed. The frequency inverter converts the fixed supply frequency (60 Hz) to a ...

Motor starter (also known as soft starter, motor soft starter) is a electronic device integrates soft start, soft stop, ...

Soft starter allows the output voltage decreases gradually to achieve soft stop, in order to protect the equipment. Such as the ...

Soft Starter reduces electric motor starting current to 2-4 times during motor start up, reduces the impact to power grid during ...

In Discussion

AODD To Electric Driven Pump

Which types of pumps are used in chilled water systems?

ICAPS simulator question

Microlense coated PV panels compared to traditional flat surface panels

transformer back charging

How much will the solar panel will cost and its production capacity

RoHS directive for power supplies

D2PAK and DPAK high power diodes

Which types of pumps are used in chilled water systems?

ICAPS simulator question

Microlense coated PV panels compared to traditional flat surface panels

transformer back charging

How much will the solar panel will cost and its production capacity

RoHS directive for power supplies

D2PAK and DPAK high power diodes